In an era defined by global uncertainty, national security is no longer just about defense; it now includes the ability to maintain stable access to goods, technologies, and critical infrastructure. Modern supply chains, while efficient, are deeply interconnected, globally distributed, and increasingly vulnerable to disruption. Yet most nations still lack full visibility into their supply chain dependencies, particularly beyond Tier-1 suppliers. This gap poses a direct threat to economic sovereignty, crisis readiness, and strategic autonomy.

This insight discusses how Generative Artificial Intelligence (GenAI) can add an intelligence layer to mitigate supply chain disruptions, enabling governments to anticipate supply shocks, model systemic vulnerabilities, and coordinate proactive responses. The study presents a clear, practical roadmap for public institutions to integrate AI into national resilience strategies, offering not just data but intelligence. As disruptions become more frequent and complex, the ability to see and act earlier will define the future of resilient nations.

1. Introduction: The Strategic Importance of Supply Chains

Global supply chains are the complex systems that move goods from where they are made to where they are needed. They encompass every stage of production and distribution, from raw material extraction and multi-tier manufacturing to transportation, warehousing, and final delivery. These networks stretch across countries and continents, linking suppliers, factories, and logistics providers into coordinated webs of economic activity. Although often invisible to the end consumer, supply chains are the backbone of the global economy. They power essential industries such as electronics, automotive, pharmaceuticals, energy, and agriculture, and underpin nearly every aspect of daily life.

For decades, supply chains have been designed for efficiency. Companies have embraced lean operations, global sourcing, and just-in-time delivery models to reduce costs and maximize speed. These models have helped unlock unprecedented productivity and global integration. However, as the world has grown more interconnected, supply chains have also grown more complex and, as recent events have made clear, more fragile. Disruptions caused by natural disasters, pandemics, trade disputes, and geopolitical conflict have exposed the limitations of conventional approaches. Today’s supply chains are not only vast and interconnected but also vulnerable to cascading failures.

While much of the responsibility for building resilient supply chains lies with private companies, governments can no longer afford to treat supply chains as a purely corporate concern. In a deeply globalized world, supply chain stability has become a matter of national security. A country’s ability to maintain critical infrastructure, ensure access to essential goods, protect strategic industries, and respond to emergencies increasingly depends on the resilience of its supply chains. When those chains break, the consequences ripple across borders, economies, and societies. This raises an urgent question: how can nations safeguard their economic and strategic interests in the face of increasingly frequent and unpredictable disruptions?

To address these vulnerabilities, governments must first understand what their economies depend on, who are they connected to? Most companies, and by extension, most national authorities, know their Tier-1 suppliers. But beyond that lies a vast and often hidden web of Tier-2, Tier-3, and even Tier-6 suppliers. These extended suppliers provide the raw materials, components, and sub-assemblies that feed into the supply chain further upstream, yet they remain a blind spot.

This lack of visibility into the deeper layers of the supply network is particularly dangerous because that is precisely where most disruptions begin. A recent study by Berger et al. [2023] shows that while companies focus on their direct suppliers, nearly over 50% of disruptions originate beyond Tier-1. Shockingly, only 6% of firms report having full visibility across their extended network [GEODIS, 2020]. This means that most companies are flying blind. When a critical material becomes unavailable or a sub-tier factory halts production, firms downstream may only learn of it after delays or failures have already occurred.

This blind spot dramatically reduces the time available to act. In resilience planning, two metrics are critical: time-to-survive (TTS), how long operations can continue after a disruption without halting, and time-to-recover (TTR), how long it takes to return to full operational capacity [Simchi-Levi et al., 2014]. When disruptions go undetected in the deeper tiers of the network, both TTS and TTR collapse. Companies lose the ability to respond effectively. But when early warning mechanisms are in place, organizations gain something vital: time. Time to secure alternative suppliers. Time to reroute logistics. Time to act before consequences cascade.

Improving visibility into the extended supply chain is therefore essential. It is not just a corporate challenge; it is a national one. When countries depend on global inputs for core industries, they must know where those inputs come from. They must monitor changes, detect risks early, and plan responses before problems cascade. Visibility enables proactivity. And proactivity protects national resilience. If companies within a country are deeply dependent on vulnerable imports or upstream foreign suppliers, governments must ask: How can we see deeper into our supply chains, before disruption strikes, such that we can act faster, smarter, and as a nation, more securely?

2. When the Chain Breaks: Real-World Disruptions and National Consequences

2.1 The COVID-19 Pandemic

The urgency of achieving deeper visibility into supply chains became vital during the COVID-19 pandemic. What began as a public health crisis quickly cascaded into a global supply shock, disrupting nearly every industry and region. As countries imposed lockdowns and transportation halted, global logistics networks strained under unprecedented pressure. Manufacturing sites were shuttered due to quarantines and workforce shortages. Meanwhile, demand for critical goods, particularly medical supplies and household essentials, spiked dramatically [Queiroz et al., 2022].

The pandemic exposed a dangerous truth: many national economies were heavily reliant on a handful of overseas suppliers and maintained little inventory buffer. Medical supply chains proved especially fragile. Over 90 governments responded by imposing export bans and restrictions on key protective equipment and medicines, hoping to secure their own access. Yet these self-protective measures often worsened the shortages. Hospitals in even the most developed countries found themselves without basic personal protective equipment (PPE), ventilator components, or essential pharmaceuticals.

The underlying cause was not a lack of global capacity; it was a lack of coordination and transparency. Lean supply chains, built for speed and efficiency, were unprepared for a system-wide shock. A single factory closure in one region or a port delay in another could send ripples across the globe. COVID-19 laid bare a hard truth: when visibility ends at Tier-1, countries are left in the dark. And when disruption strikes, this blind spot can endanger lives, stall recovery, and erode national confidence in critical infrastructure.

2.2 Geopolitical Conflicts: The Russia-Ukraine War

Geopolitical tensions are no longer confined to the realm of diplomacy; they now shape the stability of global supply chains. The Russia-Ukraine war, which started in 2022, sent shockwaves through key industries around the world by disrupting the flow of critical materials. Together, Russia and Ukraine had accounted for nearly 30% of global wheat exports and 20% of corn, placing them at the heart of the global food supply [Allen, 2022]. When the conflict began, major food-importing regions in Africa, the Middle East, and parts of Asia were among the first to feel the impact, with prices rising and availability declining.

But the disruption went far beyond agriculture. Ukraine supplied nearly half of the world’s neon gas, an essential input in the lasers used for semiconductor lithography. Russia, on the other hand, was responsible for about 40% of global palladium production, a metal crucial for catalytic converters, electronics, and aerospace components [Kilpatrick, 2022]. When access to these materials was suddenly cut, the price of palladium surged by more than 80% in the weeks following the invasion [Kilpatrick, 2022], squeezing margins for automakers and electronic producers across Europe, Asia, and North America.

Germany’s automotive sector, in particular, was severely affected. Though many German firms had diversified their Tier-1 suppliers, they were unaware of how deeply embedded Russian palladium was in their Tier-3 and Tier-4 suppliers. Production delays, soaring costs, and temporary factory closures followed. The war revealed how dependency on a single region, even for a small but strategic component, can jeopardize national industries.

For governments, this disruption carries a clear message: without visibility into extended supply chains, even well-prepared economies remain exposed. Dependencies on seemingly minor inputs, when aggregated at scale, create systemic risk. And when these inputs are sourced from geopolitically unstable regions, that risk becomes a national vulnerability.

2.3 Policy Shocks and the Fragility of Global Trade

While natural disasters and geopolitical conflicts grab headlines, policy-driven disruptions often strike more quietly, but no less forcefully. Trade tensions between major powers have steadily introduced volatility into supply flows, especially between the United States and China. Over the past several years, this rivalry has escalated tariffs, export controls, and restrictions on high-tech goods. Each round of policy action adds friction, forcing companies to adjust their supply networks in real time.

In recent years, U.S. export controls on advanced chips and fabrication equipment have aimed to protect sensitive technologies. In response, China introduced curbs on rare earth elements, including gallium and germanium, materials essential for electronics and defense systems. These policy moves ripple across borders. Electronics manufacturers faced extreme challenges to qualify alternative sources while simultaneously rerouting assembly operations to avoid tariffs. The result is a fragmented trading system where the rules change rapidly, and firms must continually reconfigure supply chains under pressure.

This dynamic exposes a deeper issue. A single decision made in one capital can cascade across the global economy. What begins as a targeted policy shift can end in widespread shortages, cost spikes, or significant delays. Each new control, ban, or sanction compounds the uncertainty facing industries that rely on predictable global access to materials and technology. Crucially, all of these disruptions, whether triggered by war, pandemic, or policy, share one important trait: their consequences are transnational. A fire in a supplier’s factory in Asia can stall an assembly line in Europe. A ban on rare earth exports in one region can leave defense manufacturers elsewhere without essential inputs. The ripple effects of supply chain breaks are not constrained by borders, and no nation is immune to the fallout.

For governments, the implications are stark. Supply chain resilience is no longer just a business concern; it is a national goal. Ensuring access to critical goods, from semiconductors to medical equipment, is now integral to safeguarding economic stability and strategic autonomy.

The path forward starts with clarity. Governments must map the extended supply chain dependencies of domestic industries, beyond direct suppliers and down into the deeper tiers. This means identifying chokepoints, tracing high-risk components to their sources, and understanding how a disruption in one link could cascade across the system. However, information alone is not enough. Supply chain data is vast, fragmented, and scattered across silos. It lives in company procurement systems, trade databases, customs declarations, shipping records, and unstructured news reports. No single actor, public or private, holds the full picture. This fragmentation is a critical barrier.

What governments now require is a way to bring this information together, to turn disconnected information into actionable intelligence. In the next section, we explore how advanced Artificial Intelligence (AI) systems can help centralize diverse data sources, monitor supply chain developments in real time, and support national-level risk detection and decision-making. Visibility is the foundation. Intelligence is the next layer. And in times of crisis, foresight becomes the most valuable tool of all.

3. AI for National Supply Chain Resilience: Building a New Intelligence Layer

In an era of increasing complexity and accelerating disruptions, governments must move beyond reactive supply chain strategies. The conventional tools, manual risk assessments, static reports, and fragmented data systems are no longer sufficient. To build true national resilience, policymakers need a live, dynamic view of their supply networks. This means more than gathering data. It means transforming data into insight, and insight into action. Artificial Intelligence, particularly in the form of Generative AI and agentic systems, offers a new intelligence layer capable of doing just that.

At its core, supply chain resilience is an information problem. Critical data is scattered across private companies, public registries, customs databases, shipping manifests, supplier websites, trade filings, and breaking news. Much of this data is unstructured, buried in PDFs, reports, emails, or web articles. No central authority sees the full picture. What is needed is a layer that can ingest all this diverse information and transform it into a structured, navigable knowledge base of supply chain dependencies and risks.

Generative AI, and in particular Large Language Models (LLMs), are well-suited to this task. LLMs can process and extract relevant entities and relationships from massive volumes of unstructured text [AlMahri et al., 2024]. They can identify supplier-product-country links, extract signals from financial disclosures, spot patterns in shipping routes, and summarize real-time disruptions reported in the media. This makes them ideal engines for turning messy, fragmented data into organized, searchable supply chain maps. Early use cases of LLMs in other industries demonstrate a huge potential: in finance, LLMs have been used to mine earnings calls and filings for market sentiment and early warnings [Wu et al. 2023]; in healthcare, they assist in analyzing clinical trial reports, adverse event filings, and research publications to identify drug risks and patient outcomes [Nori et al. 2023].

Once raw data is centralized and structured, it becomes possible to build a dynamic knowledge graph, a real-time map of national supply chain interdependencies. This map would link companies to suppliers, suppliers to materials, materials to products, and all of these to locations, risks, and geopolitical contexts. Governments could then visualize which sectors are exposed to which inputs, from where, and through whom. For example, a query might reveal that a country’s renewable energy sector depends on rare earths sourced indirectly through a Tier-3 supplier in Southeast Asia. This kind of visibility enables strategic foresight and targeted policy intervention.

But intelligence does not stop at structure. On top of this knowledge graph, governments can deploy a second AI layer: autonomous LLM-powered agents. These agentic systems are purpose-driven AI entities that can independently carry out complex monitoring, reasoning, and response tasks. One agent might be tasked with scanning the news for disruption signals related to critical minerals. Another may continuously update risk scores based on volatility in supplier regions. A third might search for alternative suppliers based on predefined thresholds of risk and cost. Each agent operates semi-independently, but together they form a coordinated system that constantly learns and adapts. This division of labor mirrors how human teams operate under pressure, allowing governments to scale insight generation across the entire supply chain landscape.

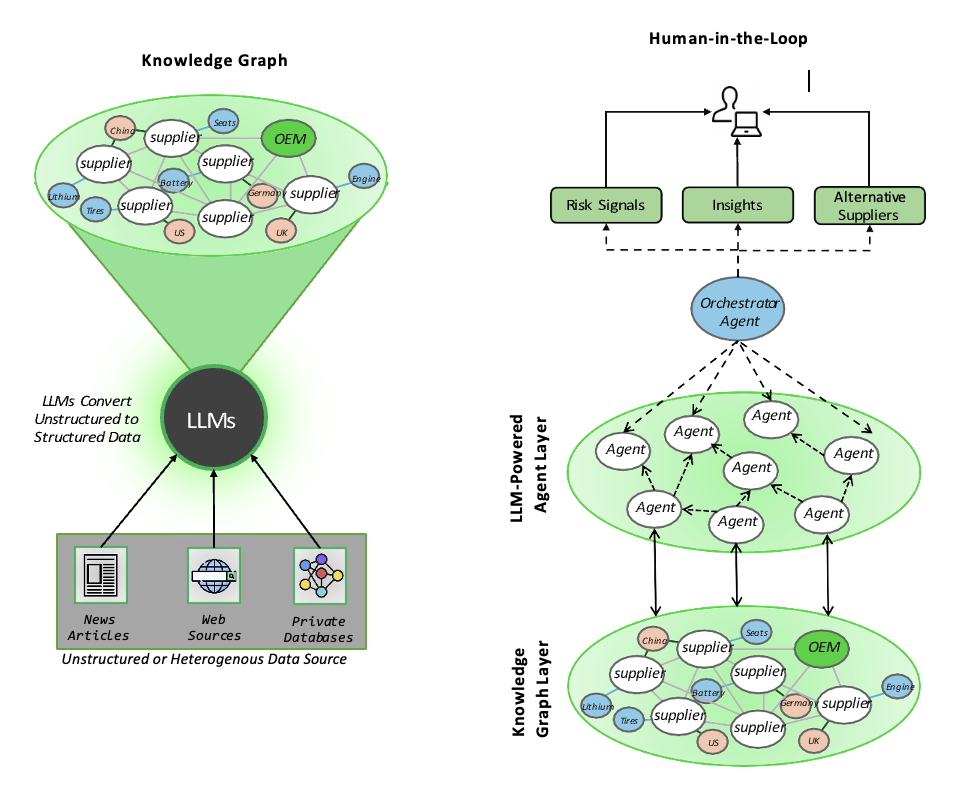

This two-layer architecture (see Figure 1), LLMs for centralizing and structuring information, and agents for acting on it, forms a scalable blueprint for national supply chain intelligence. At the base is data. On top of it is structured knowledge. And above that sits intelligence: the capacity to monitor, reason, and decide. Such a system would not replace human decision-makers but empower them. It would act as a force multiplier, extending their ability to see, think, and respond to risks that were previously invisible or too slow to detect.

Crucially, the benefit of this system lies in anticipation. Most supply chain strategies today are reactive: disruptions are dealt with after they occur. But with a national AI-powered layer, it becomes possible to move upstream, to detect risks before they escalate, model scenarios in advance, and make decisions with context and foresight. That means less scrambling for alternatives, fewer panicked policy responses, and a stronger baseline of national readiness.

In the following section, we translate this architecture into practical recommendations for how governments can begin applying AI to their national supply chain oversight frameworks. From mapping strategic sectors to deploying targeted monitoring agents, we outline steps that any government, regardless of size or digital maturity, can take to strengthen resilience through AI.

Figure 1: Two-Layer Architecture: LLMs convert unstructured text to structured centralized Knowledge Graphs. LLM-Powered Agent Layer to interact with the knowledge layer to generate insights

4. Practical Applications for Government Supply Chain Oversight

To translate this architecture into national capability, governments must approach AI not as a replacement for human expertise, but as a force multiplier. One of the most powerful ways to operationalize this intelligence is through a two-layered system that integrates LLMs and autonomous agents. Each layer serves a different purpose, yet both are essential for proactive supply chain governance.

The first layer, Large Language Models, acts as the engine for knowledge extraction. LLMs can continuously scrape and process data from diverse public and private sources: news media, trade databases, customs records, supplier websites, SEC filings, scientific reports, shipping manifests, and government procurement documents. These models convert the raw, unstructured data into structured triples, such as [Supplier X] supplies [Material Y] to [Factory Z] in [Country C], and feed them into a dynamic knowledge graph. This centralized map becomes a living asset, updated in real time, and able to answer critical questions: What products rely on suppliers in high-risk regions? Which sectors are vulnerable to specific commodity shocks? What new chokepoints are emerging across the global trade network?

Once this centralized graph exists, the second layer comes into play: agentic systems. Each agent in this layer can be programmed for a specific function, monitoring disruptions, flagging policy changes, tracing product dependencies, suggesting supplier alternatives, or generating risk reports for strategic sectors. This breaks down a complex challenge into manageable parts. For instance, a Disruption Monitoring Agent can scan the graph for links between regions in conflict and raw material supply chains. A Substitution Agent can assess the feasibility and impact of switching suppliers in response to a detected risk. These agents do not work in isolation; they interact and escalate insights, much like a digital team of analysts operating around the clock.

This AI-powered system can support governments in four critical oversight areas:

- Strategic Sector Mapping: By tracing critical dependencies across industrial sectors, governments can understand what industries matter most and what imports or suppliers those industries depend on, directly and indirectly.

- Real-Time Risk Monitoring: Agentic systems can act as a national early-warning capability, flagging disruptions as they unfold and providing sector-specific impact assessments.

- Resilience Simulation and Planning: AI can model hypothetical disruptions, such as a port closure, export ban, or cyberattack, and assess how cascading effects would impact the This helps design mitigation strategies and policy buffers.

- Crisis Decision Support: During real-world shocks, centralized insights reduce confusion and decision fatigue. Policy leaders can get a clear picture of vulnerable sectors, mitigation options, and recovery paths within minutes, not weeks.

Each of these applications shifts the role of government from relying on passive strategies to adopting proactive intelligence. Rather than reacting once damage is visible, nations can respond when the first signal of disruption emerges, and, in some cases, even before.

5. Conclusion and Strategic Recommendations

Supply chains are no longer the invisible infrastructure of globalization. They are now visible fault lines that can threaten national security, economic stability, and strategic autonomy. As disruptions become more frequent and more complex, governments must evolve beyond static oversight and build adaptive capabilities that reflect the scale and speed of global trade.

This insight has outlined how emerging AI technologies, specifically the fusion of Generative AI and agentic systems, can be used to construct a new national intelligence layer for supply chains. These technologies do not simply automate tasks; they enable a new way of seeing, reasoning, and responding to global interdependencies.

To harness this potential, we offer five strategic recommendations:

- Build a National Supply Chain Knowledge Graph: Begin with data. Partner with firms, ports, customs offices, and logistics platforms to aggregate and standardize Use LLMs to structure this data into a dynamic graph that reflects true interdependencies across sectors and borders.

- Deploy Specialized Monitoring Agents: Assign digital agents to monitor disruption signals, scan for policy changes, and trace sectoral vulnerabilities. These agents become your national eyes and ears across a fast-moving world.

- Integrate Human-AI Decision Loops: Ensure that analysts and policymakers interact directly with the AI system. Use insights to guide decisions, but maintain clear lines of accountability and strategic control.

- Institutionalize Foresight: Move beyond Use the system to model forward-looking scenarios, test policy interventions, and prepare resilience plans in advance, not after the next crisis begins.

- Treat Supply Chain Intelligence as a National Asset: Invest in this infrastructure with the same seriousness as cybersecurity or defense. It is not a back-office function. It is core to strategic

Ultimately, the goal is not just to prevent the next disruption. It is to build nations that can learn, adapt, and recover faster than ever before. With the right architecture, AI becomes more than a tool; it becomes a strategic capability. And with it, governments can turn supply chain fragility into a foundation for strength.

References

Daniel Allen, “Supplied Unchained: The Russia-Ukraine War Impacts Global Industry,” DirectIndustry: e-Magazine, 2022, Accessed: June 30, 2025, https://emag.directindustry.com/2022/03/15/ supplies-unchained-how-the-russia-ukraine-war-impacts-global-industry/.

Sara AlMahri, Liming Xu, and Alexandra Brintrup, “Enhancing supply chain visibility with knowledge graphs and large language models,” arXiv, 2024, https://arxiv.org/abs/2408.07705.

Niklas Berger, Stefan Schulze-Schwering, Elisa Long, and Stefan Spinler, “Risk management of supply chain disruptions: An epidemic modeling approach,” European Journal of Operational Research 304, no. 3 (2023): 1036–1051.

GEODIS, “Supply Chain Worldwide Survey (UK),” 2020, https://geodis.com/sites/default/files/2021-07/GEODIS%20RA_RSE_2020_UK.pdf.,Retrieved July 2021.

Jim Kilpatrick, “Supply chain implications of the Russia-Ukraine conflict,” Deloitte Insights, 2022, https:

//www.deloitte.com/us/en/insights/topics/supply-chain/supply-chain-war-russia-ukraine. html. Accessed: June 30, 2025.

Harsha Nori, Nicholas King, Scott M McKinney, Dean Carignan, and Eric Horvitz, “Capabilities of GPT-4 on Medical Challenge Problems,” arXiv, 2023, https://arxiv.org/abs/2303.13375.

Maciel M Queiroz, Dmitry Ivanov, Alexandre Dolgui, and Samuel Fosso Wamba, “Impacts of epidemic outbreaks on supply chains: mapping a research agenda amid the covid-19 pandemic through a structured literature review,” Annals of Operations Research 319, no. 1 (2022): 1159–1196.

David Simchi-Levi, William Schmidt, and Yehua Wei, “From superstorms to factory fires: Managing unpre- dictable supply chain disruptions,” Harvard Business Review 92, no. 1-2 (2014): 96–101.

Shijie Wu, Alexander Jaegle, Tarun Chhabra, Trishul Bansal, Sergey Edunov, Omer Polozov, and Eric Smith, “BloombergGPT: A Large Language Model for Finance,” arXiv, 2023, https://arxiv.org/abs/2303.17564.